INTEGRATED MANAGEMENT SYSTEM

WHY IMPLEMENT AN INTEGRATED MANAGEMENT SYSTEM?

An Integrated Management System (IMS) integrates all of an organization’s systems and processes in to one complete framework, enabling an organization to work as a single unit with unified objectives.

The main industrial accidents and environmental damages worldwide have been caused by activities of companies that have certified integrated management systems, and that in papers fulfill all the requirements that the human and extraterrestrial mind can conceive.

The industry has become accustomed to developing projects assuming risks under the hypothesis of compliance with previously defined norms, which at the time of their concrete application turn out to be ineffective, bureaucratic and consequently do not fulfill their function.

The central problem is that the principles of Integrated Management Systems (IMS's), which are very good and contribute to the process of continuous improvement, have been degraded over time. The pursuit of perfection requires ensuring the sustainability of human interventions over short-term profit. Failure to comply with standards should generate a process of reflection rather than the drafting of new standards, to regulate the existing standard. Is it a tongue twister? No, it's reality.

Voluntarily, the principles established in the formulation of IMS's, have been met by Ingeniería del Agua SRL (IA) since its founding. The decision to implement a formal IMS is due to the need to document key management factors that allow the engineering study to be consolidated. The IMS that it has is its own, adapted to the specific needs of the work carried out, and above all is concise and coherent, to ensure results and effectively promote a system of continuous improvement in search of unreachable perfection.

AREAS OF INTEREST

IA is an engineering consultancy, and its scope is limited to the conception and development of projects, overseeing its implementation and commissioning. Its installed capacity allows it to assume responsibilities in operation and maintenance. It is in this context that the areas of interest have been identified, according to the following detail:

APPLICABLE STANDARDS

An Integrated Management System (IMS) integrates all of an organization’s systems and processes in to one complete framework, enabling an organization to work as a single unit with unified objectives.

The main industrial accidents and environmental damages worldwide have been caused by activities of companies that have certified integrated management systems, and that in papers fulfill all the requirements that the human and extraterrestrial mind can conceive.

The industry has become accustomed to developing projects assuming risks under the hypothesis of compliance with previously defined norms, which at the time of their concrete application turn out to be ineffective, bureaucratic and consequently do not fulfill their function.

The central problem is that the principles of Integrated Management Systems (IMS's), which are very good and contribute to the process of continuous improvement, have been degraded over time. The pursuit of perfection requires ensuring the sustainability of human interventions over short-term profit. Failure to comply with standards should generate a process of reflection rather than the drafting of new standards, to regulate the existing standard. Is it a tongue twister? No, it's reality.

Voluntarily, the principles established in the formulation of IMS's, have been met by Ingeniería del Agua SRL (IA) since its founding. The decision to implement a formal IMS is due to the need to document key management factors that allow the engineering study to be consolidated. The IMS that it has is its own, adapted to the specific needs of the work carried out, and above all is concise and coherent, to ensure results and effectively promote a system of continuous improvement in search of unreachable perfection.

AREAS OF INTEREST

IA is an engineering consultancy, and its scope is limited to the conception and development of projects, overseeing its implementation and commissioning. Its installed capacity allows it to assume responsibilities in operation and maintenance. It is in this context that the areas of interest have been identified, according to the following detail:

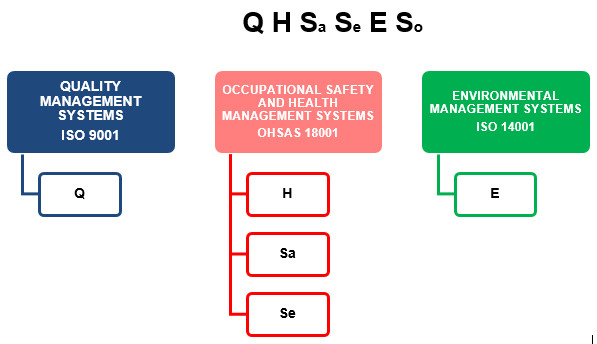

- Quality / Quality (Q).

- Health / Health (H).

- Safety and Industrial Hygiene / Safety (Sa).

- Social Security.

- Environment (E).

- Social Responsibility (So).

APPLICABLE STANDARDS